Daily callouts, repairing damaged machines, equipment, and pipes, cleaning filters, ensuring compliance...

Our site managers define operating procedures and draw on human and material resources to implement the operator's maintenance plans. They also provide improvement ideas and proposals.

Flexibility, finding solutions, mutual trust, and the digitisation of service reports make interactions more manageable and help maximise the availability of the facilities and operational safety while keeping costs under control.

Verdon's maintenance teams are trained in risk management when working at height, in confined spaces, in ATEX zones, and in high-risk Seveso sites. Safety is their top priority.

With the right mindset and solidarity amongst its workforce, Verdon can respond immediately to all needs, including the exceptional situations that plant operators sometimes face.

Verdon understands the typical constraints of major shutdowns, such as planning, stakeholder coordination, co-activity control, lockout procedures, parts, and purchase order management...

Our recruitment channels allow us to mobilise qualified staff on short notice and for periods of a few weeks.

With our testing, vibration analysis, oil analysis, ultrasound analysis and infrared thermography tools, Verdon can assess your installations and equipment to determine the causes of failure.

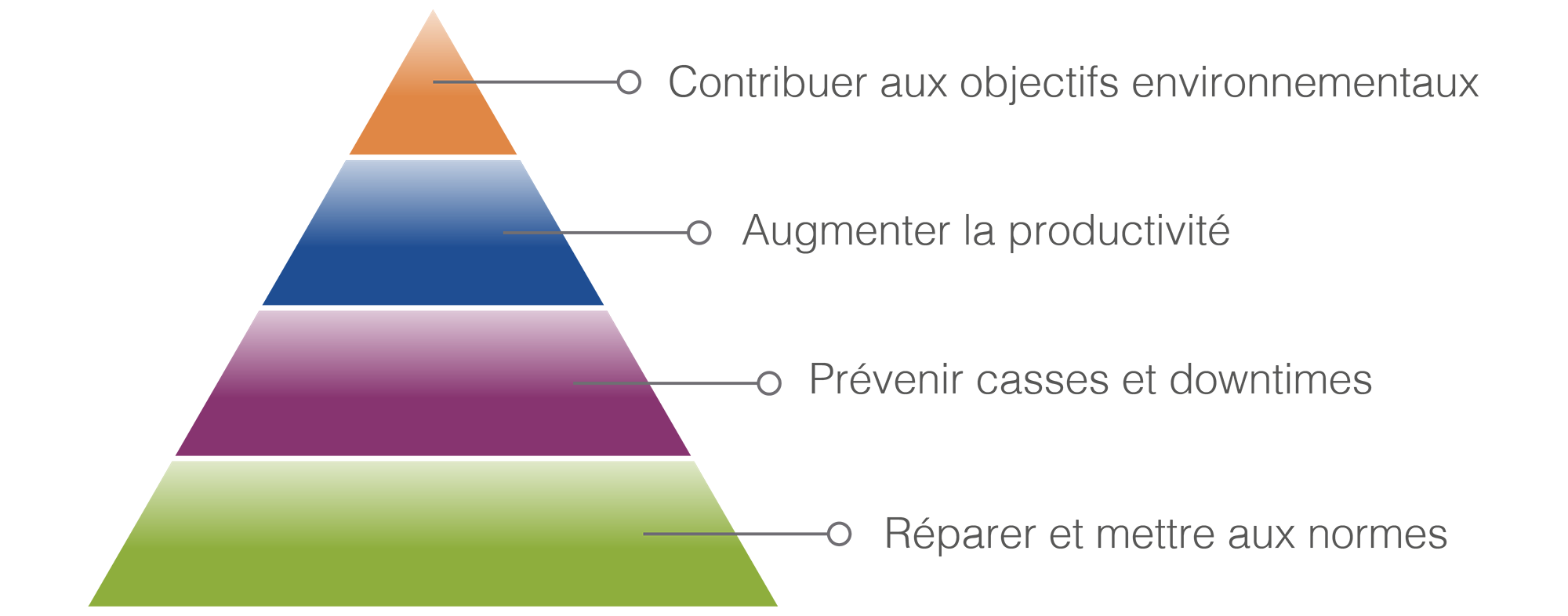

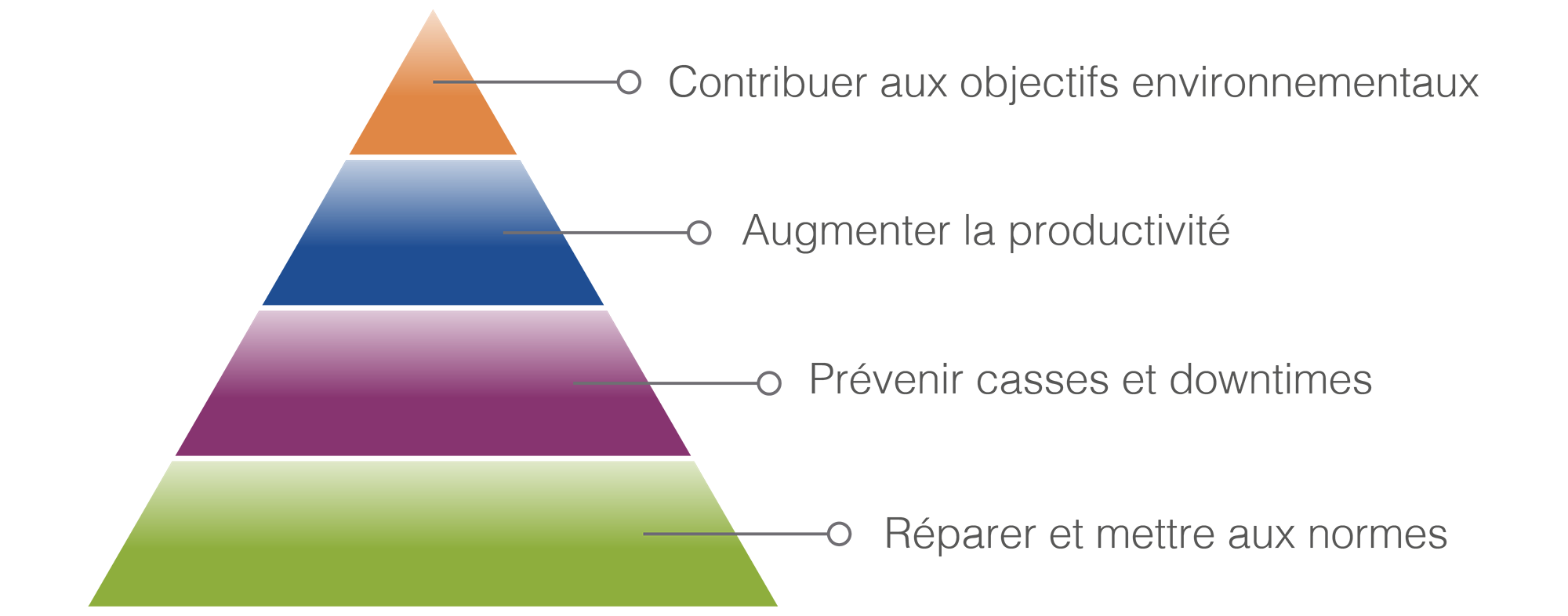

These tools allow us to implement concrete and proven optimisation methods (availability of equipment, machine performance and quality of the materials produced), prevent breakages and contribute to the company's environmental objectives, for example, by cleaning (flushing) in a closed circuit rather than down the drain or by detecting compressed air leaks.