Vital arteries carrying hazardous or pressurised fluids. Vital arteries on which the operation of nuclear power plants, airports and datacenters depend. Verdon's quality assurance system, based on ISO 9001 and the GMP, has been audited and validated by our main customers. The Verdon factory in Belgium is certified EN1090 FPC+2.

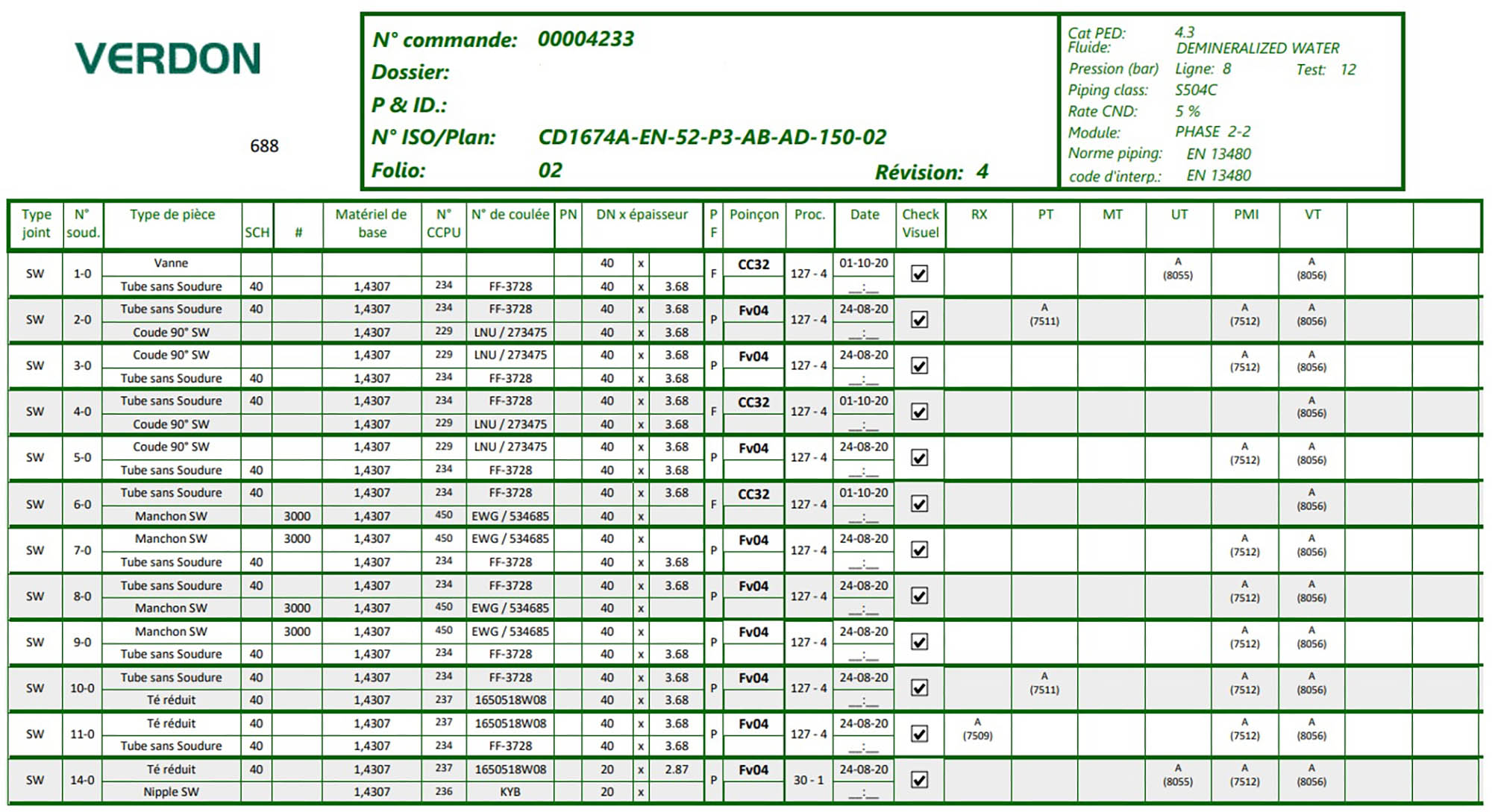

Our as built and technical specification documentation meet all requirements for traceability and the quality assurance of work in the most sensitive sectors.

Certifications, production monitoring, quality controls, systematic testing, as well as checked and calibrated measuring equipment, all guarantee the reliability of our services. Verdon’s range of tools also undergoes a rigorous maintenance programme. All our business activities are divided and described in procedures that specify the operational provisions for quality.

At the heart of the system is the Quality™ production ERP developed specifically for and by Verdon.

It allows a complete tracking of all the modifications and almost real-time progress monitoring, both for prefabrication in the workshop and on-site work.

For each line and each point on our isometrics, we find:

Technicians use tablets with an application developed by Verdon to fill in the service reports and get the customer's sign-off. The late can add comments and rank the intervention on quality, effectiveness, adherence to safety procedures and overall performance. Information is available in real-time, without any encoding. Combined with connected punch card terminals, they provide precise service monitoring and error-free invoicing.

All raw materials or components used in production or serviced on-site by Verdon technicians are fully labelled, identified with a QR code and automatically listed in our ERP.

All raw materials or components used in production or serviced on-site by Verdon technicians are fully labelled, identified with a QR code and automatically listed in our ERP.